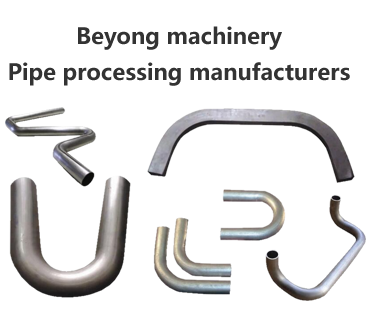

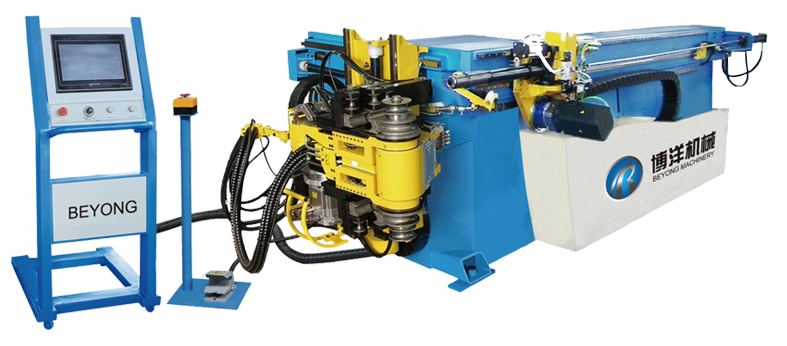

| The bending machine system |

| 发布者:admin 点击:861 |

We introduce this large bending machine is in the 02 year of Sinopec pipeline storage and transportation company pipeline technology operation branch company developed specifically applied to crude oil, finished oil long-distance pipeline construction of pipe bending machine. The bending machine is mainly composed of a pipe bending machine comprises a driving device, a guide wheel device, a pressing device, the rocker arm rotating device, clamping device, a base, intermediate frequency power source, hydraulic system components. Rocker arm rotating device is a pipe bending machine core component, its action is the heated tube bent to conform to specified requirements the radius, with curved, rotary, reducing function. The device can bending diameter of 219 ~ 762 mm steel pipe, bending radius of 650 ~ 4500 mm, bending, bending radius of many kinds of large variation range. Equipment has the advantages of reasonable structure, reliable performance, stable running and bending high efficiency, easy operation and so on. Below I introduce in detail the principle and composition of the rocker arm rotating device: Rocker arm rotating device mainly comprises a large slipway, rocker arm, rocker arm driving device, the middle slipway, slewing bearing, small slipway and other components, the whole structure as shown in figure 1. The rocker driving device installed in the large slipway side, rocker arm through a rotary bearing is fixed on the sliding table fixed on the rocker arm, the middle slipway, large changes in position, sliding, thus adjusting the rotation center and chuck distance between center line, i.e. adjusting pipe bending radius. , bend, rocker bearing circumferential force and resistance moment, the rocker arm is driven by a rocker arm device drags the return, return rate is 2.2 R / min. Rocker arm rotating device adjusts the bend radius, start in the hydraulic motor, moving table table, through the slide ruler, the chuck center located in the required dimensions, closed hydraulic motor; through the gear and rack mechanism, to move the small table, with a positioning pin small slipway is fixed in the sliding table, rotating the top thread, the chuck top tight, complete chuck positioning; start the big table motor, mobile sliding table table, so that the center of the chuck and the guide wheel device is aligned with the center, close the motor starting motor; a clamping oil cylinder, the sliding table worktable clamping, the worktable ( rocker rotating center position ). Bend, rocker driving device does not work, the rocker arm rotating device is composed of a main driving device driven by a circumferential force and resistance moment, bear. Rocker arm return is driven by a rocker arm device drive, operation, closed electromagnetic clutch, a hydraulic motor starting, rocker driving device to drive the rotary device to rotate, the rocker arm back in situ, closed hydraulic motors, disconnect the electromagnetic clutch, to prepare for the next operation. Administered by the urge, subjected to circumferential force and resistance moment. Rocker arm return is driven by a rocker arm device drive, operation, closed electromagnetic clutch, a hydraulic motor starting, rocker driving device to drive the rotary device to rotate, the rocker arm back in situ, closed hydraulic motors, disconnect the electromagnetic clutch, to prepare for the next operation. Rocker arm rotating device performance directly determines the pipe size precision and shape index, therefore, must have enough strength, stiffness, size precision, especially has good rotary accuracy. |

| The previous page:Piping installation process, what kind of pipe bending machine will be use? The next page:Pipe bending machine principle of work |

|